Japan Shaft Manufacturing Co., Ltd. Business Introduction

We promise speedy and accurate delivery of special steel, which is active in various industrial fields, with a rich inventory.

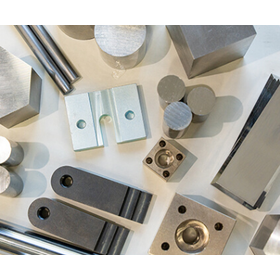

Japan Shaft Manufacturing Co., Ltd. responds broadly to the needs of manufacturers in industries such as industrial machinery, agricultural machinery, the automotive industry, printing machinery, and building materials/construction machinery. With the motto "immediately usable polished shafts," we focus on producing round bars, square and hexagonal materials, and various shaped drawn materials. We handle a wide range of steel materials, including polished round steel, general structural steel, bearing steel, and carbon tool steel, with a rich inventory. We have introduced a state-of-the-art fully automatic circular saw cutting machine capable of cutting from Φ10mm to Φ160mm, establishing a supply system that ensures reliable quality and short delivery times for round materials, square materials, and pipe materials. 【Business Activities】 ■ Processing and sales of drawn steel shafts (polished round steel) ■ Processing and sales of other ferrous and non-ferrous metals *For more details, please feel free to contact us.

- Company:日本シャフト製造 千葉工場

- Price:Other